Environmental Hygiene

To record and control the microbiological status in the environment of food processing, ifp offers sampling of hygiene samples

Generally, there are various techniques to test surfaces, furnishings, food contact materials and personnel/clothing:

- Swab method

- Squeeze method

- Wiper method

Inspection and consultations on all aspects of environmental hygiene

- Implementation and review of monitoring programmes:

sampling points, sampling methods, frequency, test parameters and evaluation of results - Verfication of cleaning and disinfection measures

- PEM (pathogen environmental monitoring)

Testing for the presence of pathogenic microorganisms in the production environment, e.g. Salmonella monitoring or Listeria monitoring - Staff monitoring

- Sampling and identification of causes in case of crisis situations and food safety incidents

- Creation and implementation of monitoring systems

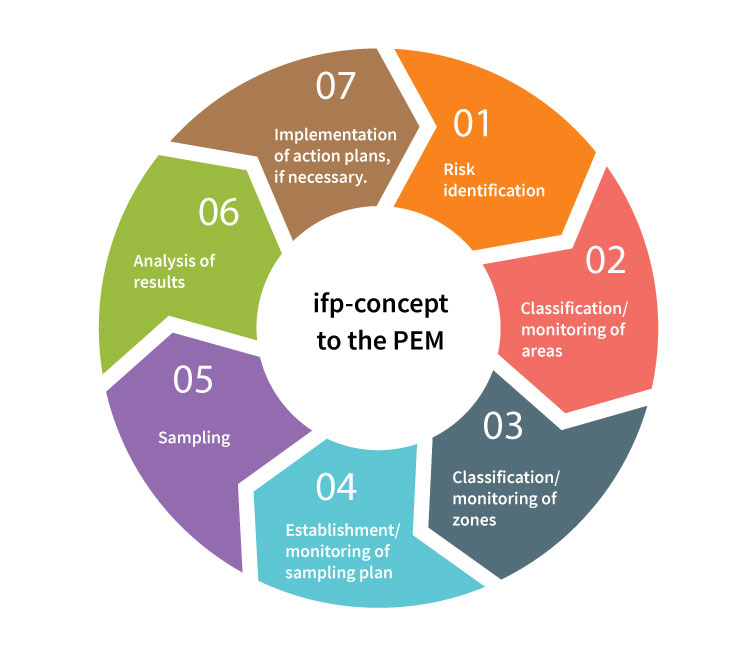

ifp concept for PEM (pathogen environmental monitoring)

General information:

Pathogen Environmental Monitoring (PEM) is a dynamic verification tool. With this tool, the probability of detection can be increased so that the risk of environmental contamination can be assessed and defined measures can be implemented. Common standards in the food industry require the PEM as a verification method.

The identification of pathogenic microorganisms such as Salmonella, Listeria and indicator germs as well as Enterobacteriaceae, coliform germs and other germs by air and water monitoring is used to to check the implementation of a good hygiene/ and manufacturing practice (GHP and GMP). This allows a quick reaction in case of environmental contamination and the fast initiation of appropriate corrective measures before product safety is threatened.

We support you with:

- Classification of the production plant into sectors

- Creation of a zone concept

- Creation of sampling plans/monitoring concepts (especially for Listeria monitoring and Salmonella monitoring)

- Choice and provision of materials

- Staff training

- Sampling and transport to the laboratory

- Inspection/auditing of internal sampling and monitoring systems

After the concept implementation:

- Regular realization of the sampling plans and monitoring programs

- Evaluation of the results and trends

- Updating the concept if there are changes to premises or processes

- Regular questioning of the sampling points (e.g. is this still the most critical point?)

Do you have questions, we are happy to consult you any time.