Mineral oil hydrocarbons (MOSH/MOAH)

Within a project of the BMEL from 2012, a high migration potential into food was identified for mineral oil hydrocarbons from recycled cartons. However, mineral oil components can get into food in a number of ways. Possible sources of contamination are packaging materials (recycled paper, printing inks, jute bags) as well as:

- lubricating oils from harvesting and processing machines

- exhaust gases from the environment

- dressings of corrugated board containing mineral oil

- food additives (separating agents, coating agents, glazing agents, anti-dusting agents)

What are MOSH and MOAH?

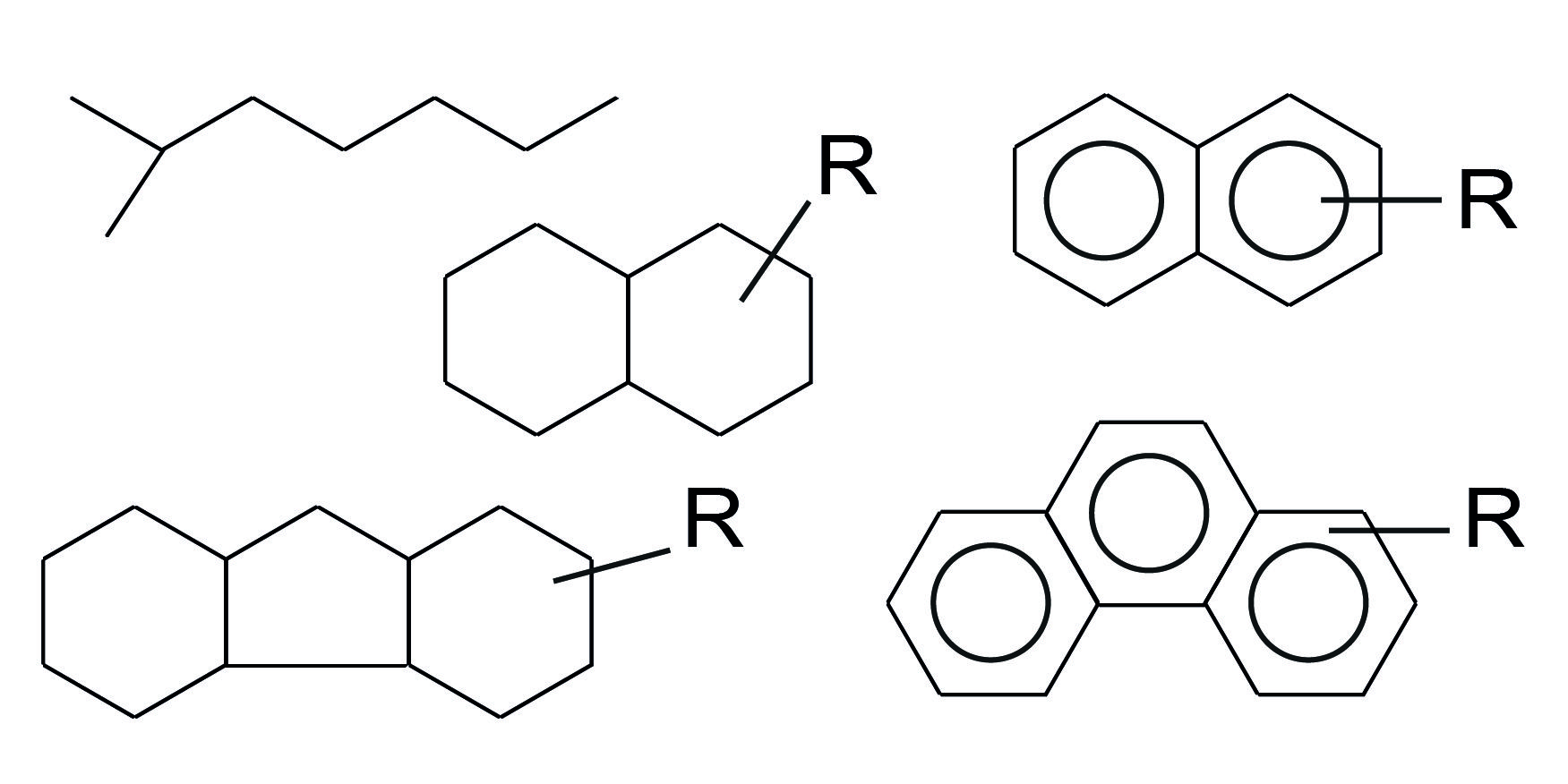

From a chemical point of view, mineral oils are complex mixtures mainly consisting of saturated hydrocarbons (MOSH) and most of the time alkylated aromatic hydrocarbons (MOAH). Both groups of substances contain linear, branched as well as ring-shaped compounds of different molecular sizes.

The chemical and percentage composition of the individual mineral oil fractions can vary greatly depending on the origin and production process of the mineral oil products obtained from crude oil. Thus, crude and technical mineral oils contain relatively high contents of MOAH, whereas refined medicinal mineral oils usually contain only traces or no detectable contents of aromatic components.

In addition, certain marker substances can provide information on the source of contamination. Diisopropylnaphthalenes (DIPN) for example are compounds that are used as solvents in carbonless papers which cannot be removed completely during the production of waste paper. Detection of DIPN in food can therefore indicate direct or indirect contact with packaging materials containing waste paper. In addition, POSH (oligomeric hydrocarbons from polyolefins) and PAO (polyalphaolefins) show characteristic signal patterns in the chromatogram of the online LC-GC-FID analysis and allow to identify a contamination with plastic components and synthetic lubricants. 1,2,3

What are the health risks and what is the legal regulation?

According to the current state of scientific knowledge, there is no sufficient toxicological evidence to prove a health risk to humans from saturated mineral oil fractions (MOSH). Meanwhile, MOAH are suspected to be carcinogenic (especially PAH-like compounds with 3-7 ring systems), therefore their levels in food should be reduced according to the ALARA-principle. (as low as reasonably achievable).

Currently, there are neither specific legal regulations nor maximum levels for mineral oil components in food. In February 2017, the 4th draft of the 22nd Ordinance amending the German Commodities Ordinance ("Mineral Oil Ordinance") was published. It provides the use of functional barriers to ensure that no detectable transition of MOAH from waste paper containing food contact materials in food takes place. A detection limit of 0.5 mg/kg of food applies here.

In 2019, the Joint Research Center of the European Commission published the JRC Guidance document on sampling, analysis and data reporting for the monitoring of mineral oil hydrocarbons in food and food contact materials. This document recommends a uniform procedure for mineral oil determination, starting with sampling and ending with the presentation of results, in order to achieve better comparability of analytical results. 4

In addition, the Ländergemeinschaft Verbraucherschutz (LAV) have published in cooperation with the Lebensmittelverband Deutschland e.V. guidance values for mineral oil in certain food categories These levels have been determined statistically and are intended to represent the current standard for the reduction of mineral oil contents according to a Good Manufacturing Practice. The guide values refer to the standardised analysis and presentation of results of the JRC guidelines. 5, 6

How is the analysis carried out at ifp?

At ifp mineral oil hydrocarbons are analysed using an online coupled HPLC-GC-FID method based on the BfR method of 2009 and DIN EN 16995. Various optimization steps have been realized in order to be able to make a more differentiated analytical assessment.

In addition, the ifp Institute for Product Quality offers a highly selective method for the validation of positive results and for further characterisation of mineral oil components using GCxGC-ToF analysis.

Following services are offered by ifp:

- analysis of food, lubricants, cardboard and plastics etc. by online coupled, in-house optimized HPLC-GC-FID

- verification of positive results and further characterisation of mineral oil components by high-resolution GC×GC-ToF

- migration and functional barrier tests on food packaging materials

- identification of sources of contamination

- planning of monitoring

We will be happy to advise you. Feel free to contact us.

Sources:

1 Final report on the scientific study "Extent of migration of undesirable substances from packaging materials made of recovered paper in food". Federal Ministry of Food, Agriculture and Consumer Protection. 2012

2 Birgit Geueke. Dossier- Mineral oil Hydrocarbons. Food Packaging Forum, June 2017, DOI: 10.5281/zenodo.820984

3 S. Biedermann-Brem et.al. Migration of polyolefin oligomeric saturated hydrocarbons (POSH) into food. Food Additives and Contaminants Vol. 29, No 3, March 2012, 449-460

4 S. Bratinova, E. Hoekstra (Editors). Guidance on sampling, analysis and data reporting for the monitoring of mineral oil hydrocarbons in food and food contact materials. Luxembourg: Publication Office of the European Union, 2019, SBN 978-92-76-00172-0, doi:2760/208879, JRC115694

5 Dr. Sieglinde Stähle, Bund für Lebensmittelrecht und Lebensmittelkunde e. V.; Rüdiger Helling, Saxon State Ministry of Social Affairs and Consumer Protection, Department 22 Food and Feed Safety, Consumer Goods, Cosmetics. Orientation values for mineral oil hydrocarbons (MOH) in food. Status April 2019

6 https://www.lebensmittelverband.de/de/aktuell/20190502-veroeffentlichung-moh-orientierungswerte