Characterisation of complex mineral oil compounds in packaging by GC×GC-ToF

The ifp Institute for Product Quality offers a highly selective method for characterising and quantifying mineral oil components in complex matrices. Thanks to our exclusive network of experts in the industry (Lab Lommatzsch & Säger; www.mosh-moah.de), our clients can benefit from many years of experience in research and method development for mineral oil analysis.

A new dimension in mineral oil analysis

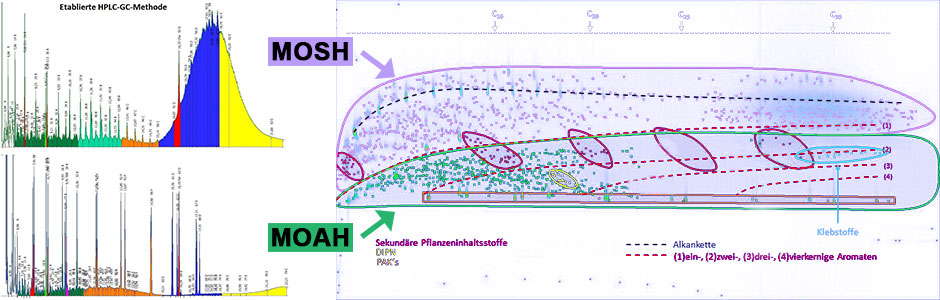

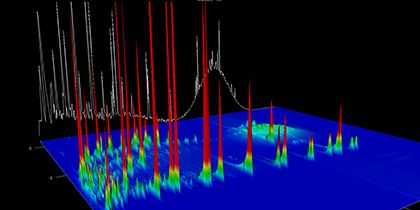

Two-dimensional gas chromatography together with a mass-selective time-of-flight detector (GCxGC-ToF) can separate mineral oil hydrocarbons (MOSH + MOAH) in complex compounds from other types of hydrocarbons (synthetic oligomers such as POSH or naturally occurring terpenes). It is also possible to obtain more detailed structure information, e.g. about the number of aromatic nuclei, existing isomers and the level of alkylation, and thereby identify the source of contamination (polyolefins, adhesives, ink formulations or grease). Thanks to the innovative pairing with an FID detector, the ifp can now quantify the individual substance groups with great sensitivity for the first time.

MOSH/MOAH in complex matrices: the limitations of conventional methods

Online HPLC-GC-FID, a long-established process which is currently routinely used, cannot chromatographically separate the substance classes MOSH (mineral oil saturated hydrocarbons) and POSH (polyolefin oligomeric saturated hydrocarbons) from each other. It can also be difficult to determine the level of aromatic mineral oil components if resin oligomers or other aromatic combinations are present.

GC×GC-ToF can overcome these limitations

The new two-dimensional GC (GC×GC) process can significantly increase the previous resolution of the mineral oil fractions (pictured). To this end, the sample extracts are pre-separated by liquid chromatography into a MOSH fraction and a MOAH fraction in the first stage. The fractions are analysed immediately by GCxGC-ToF. Firstly, fractionation takes place via a polar GC column. A thermal modulator (cold and hot jet) is used to modulate the fraction at the end of the first GC column and transfer it without loss to a second, non-polar GC column for further fractionation in the second dimension. The analyte molecules are detected using a sensitive Time of Flight (ToF) MS detector. In contrast to a flame ionisation detector (FID), detailed mass spectra with substance-specific fragment samples can be obtained in this way. The structure information obtained in combination with the much more effective two-dimensional resolution technique can be used to identify individual substances or substance groups. This means that, for the first time, potential sources of contamination can be reliably identified and any countermeasures required to prevent mineral oil contamination can be taken quickly, thus guaranteeing high product quality. Furthermore, this method is more robust in complex hydrocarbon compounds than conventional HPLC-GC-FID analytics in terms of false positive or false negative results.